Table of Contents

The current industrial scenario is inevitably impacted by emerging technologies, in which manufacturing is the most talked about. One such advanced technology internet of Things (IoT) plays a significant role in production enterprises, revolutionizing business and operational processes and enabling the creation of smart factories. It is quite evident that IoT in manufacturing is a critical driving force for the development of Industry 4.0.

Manufacturers face various challenges such as rising customer expectations, the complexity of the global supply chain, and the growing demand for customization. In order to overcome such complexities while staying competitive, they need to explore new, innovative ways. As a result, many businesses turn to digital transformation for enhancing their manufacturing and supply chain operations, seeking productivity improvements and discovering new opportunities for growth.

In the current scenario, the adoption of IoT development services is increasing as businesses want to achieve digital transformation for their manufacturing operations. The Internet of Things (IoT) primarily involves the deployment of a network of sensors to collect essential production data, which is then processed by cloud software to provide valuable insights into the efficiency of manufacturing operations.

Why is the Internet of Things Important?

The Internet of Things (IoT) is a crucial technology that is set to transform the way businesses operate. It has the potential to disrupt traditional practices and provide numerous benefits that go beyond just convenience. As IoT eliminates human interference, it further encourages automation and offers valuable insights into systems, enhancing performance and even preempting problems.

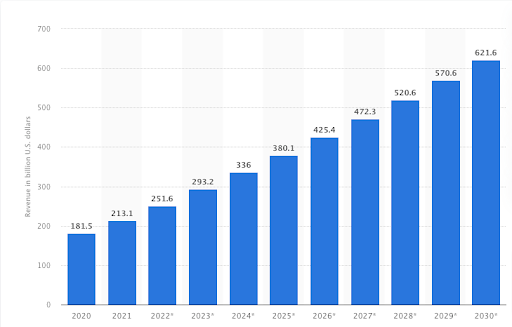

IoT is a major technological advancement that is steadily gaining traction. Its implementation in the manufacturing sector can automate processes, reduce costs, and improve customer service by providing transparent transactions through connected devices. The best part is that all such benefits are achievable without compromising. Owing to the exceptional benefits of IoT, the revenue of this technology is rapidly increasing.

According to Statista, the global value of IoT is anticipated to reach one trillion dollars by the early 2030s.

Pic Credit: Statista

Core Applications of IoT in Manufacturing

The Internet of Things (IoT) offers a mutually beneficial solution for both manufacturers and consumers. By using IoT, manufacturers can remotely monitor and repair various equipment, enabling them to scale up production. Such capability of IoT allows businesses to accurately forecast consumer demands, providing a favourable situation for all parties involved. No doubt, businesses are shifting to IoT application development to get a competitive edge and profitability.

The manufacturing domain is going through a revolutionary transformation with the use of the IoT. Networked control systems help with processes and monitoring in several facilities, and the application of IoT can be extended to various levels.

Let’s explore some of these possibilities!

-

Smart Packaging

Manufacturers can leverage smart packaging to incorporate materials with embedded systems that offer IoT benefits. One of the most significant benefits of smart packaging is that it enables customers to interact with it and generates data that can improve product management.

For instance, smart packaging may include instructional videos to showcase how to use the product. IoT and packaging can interact through various methods such as sensors, QR codes, AR, VR, and mixed reality to offer value to customers while collecting data through smart asset tracking solutions. The primary objective of IoT-based smart packaging is to enhance operational efficiency while improving customer satisfaction.

-

Remote Production Control

IoT can enable remote process monitoring and equipment configuration in manufacturing. Firstly, on-site and even off-site workers can collect data on manufacturing processes remotely and verify if they comply with specific rules and standards.

Secondly, workers can remotely adjust and configure equipment, saving considerable time and effort. However, businesses can leverage IoT technology to address various issues with performance through virtual networks without being physically present, streamlining equipment administration and control.

Employees can also keep track of the location of devices, such as movable assets, using virtual equipment monitoring.

-

Predictive Maintenance

Human involvement is no longer required to predict equipment performance abnormalities as embedded IoT sensors within machines can detect operational malfunctions such as temperature, pressure, voltage, and more. These sensors can notify officials instantly which leaves them corrective measures as soon as possible.

Predictive maintenance, also referred to as predictive repair, enables the technical support team to identify and resolve faults before they result in significant equipment failure, reducing downtime and expenses.

Furthermore, predictive maintenance enables IoT-connected equipment to integrate with advanced analytics tools to predict when technical assistance is necessary.

-

Asset Management

Manufacturers can obtain and monitor real-time information on all their assets through IoT-based web or mobile applications. Industrial asset tracking with IoT devices is possible as it allows the tracking of the following devices:

- Vehicles transporting raw materials and goods

- Warehouse items

- Production process-related resources

With the IoT, asset tracking and optimization are possible throughout the production process, from the supply chain to the finished product.

Asset monitoring facilitates the early and precise identification of errors that could adversely affect product quality or time-to-market.

-

Digital Twins

Digital twin technology encompasses the Internet of Things, AI, machine learning, and cloud computing. Digital twins play a crucial role in the digital transformation of manufacturing by serving as virtual replicas of real products. Their use on the factory floor can be highly advantageous.

Engineers and managers can simulate various processes, conduct tests, identify errors, and achieve desired outcomes using virtual duplicates of equipment and replacement parts without risking or damaging actual assets.

-

Logistics Management

logistics in the manufacturing industry are inherently risky due to weather uncertainties, the potential for fraud, and the need to manage innumerable assets. To address such issues, transportation-based companies may explore interconnecting various devices and systems through IoT technology.

IoT applications for logistics can address various use cases along the supply chain, including warehousing, fleet management, and cargo tracking, making technology a key driver of digital transformation.

In fact, there is a growing usage of drop shipping bots and lockers, which increase delivery convenience and profitability. As a result, manufacturers can also reduce shipping costs by adopting this strategy.

IoT also enables automatic order processing and status updates which reduces the requirement for delivery staff and operating costs. As mentioned that connected bots which are used for last-mile delivery can significantly reduce costs and improve customer satisfaction.

Logistics managers can use IoT for repairs and fuel expenditures, optimizing tasks such as monitoring fuel costs, smart deliveries, diagnostics, and drivers. Real-time monitoring of driver and vehicle performance enhances technician safety, reduces inventory damage, and lowers insurance payments.

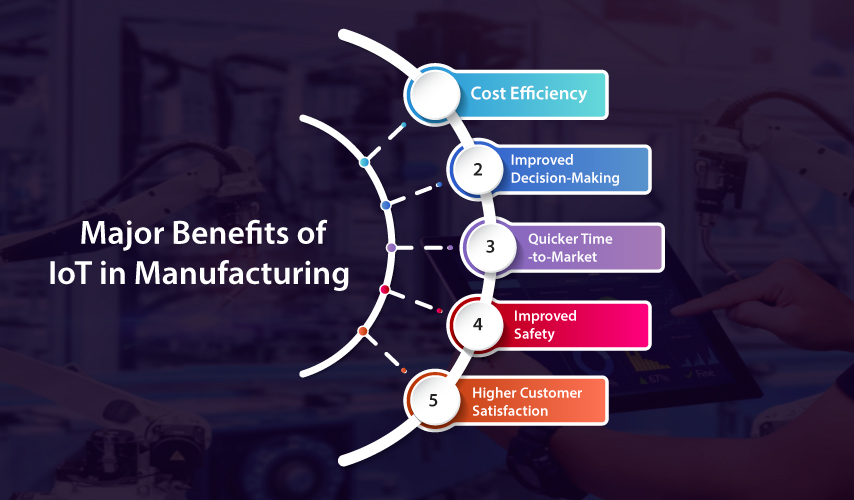

Major Benefits of IoT in Manufacturing

IoT has the potential to transform the manufacturing domain as it offers a plethora of benefits which manufacturers can leverage to enhance operations and ultimately profitability.

Here are the top benefits of IoT in manufacturing.

1. Cost Efficiency

Downtime is one of the biggest issues for the manufacturing industry as it costs significant expenses in form of energy, material, and losses. IoT drive process automation which results in a considerable reduction in operational costs. As IoT is a big driver of predictive maintenance which when combined with optimized asset management, eliminates many scope sudden issues in machines and saves money in the long run.

2. Improved Decision-Making

In order to effectively manage resources and optimize assets in manufacturing units involving both human and machine elements, having detailed data is essential. By utilising IoT-based sensors, valuable data can be collected and distributed in real time through reliable networks. As a result, it enables a rapid flow of information throughout the manufacturing facility, which allows the continuous creation of dashboard metrics that helps in broadcast results and allow decision-making.

With access to IoT technology, managers can have precise insights to stay continuously informed about the performance of their assets and devices. Therefore, it leads to faster and more well-informed decision-making.

3. Quicker Time-to-Market

The utilisation of IoT technology facilitates direct communication between employees and network components, which leads to a substantial boost in productivity. Furthermore, the ability to access data in real-time enables quicker decision-making and enhanced responsiveness to market fluctuations. The mentioned efficiency is why new products can be rapidly moved from the concept phase to commercialisation, resulting in considerable time savings.

4. Improved Safety

The use of IoT sensors to monitor various working conditions such as harmful emissions, along with wearable devices that track the health of workers in plants and factories, can significantly contribute to a safer work environment and reduce the occurrence of accidents.

5. Higher Customer Satisfaction

The behaviour of potential customers and the loyalty of clients are heavily influenced by the quality of products. Internet of Things (IoT) technology offers predictive maintenance tools and statistical evaluations that support the innovation, planning, design, construction, operation, and maintenance of industrial facilities, resulting in enhanced product quality.

Moreover, connected devices can eliminate human error and prevent the distribution of faulty products which leads to a substantial improvement in customer satisfaction.

The Ending Note

IoT can give a massive boost to the manufacturing industry with the kind of benefits this technology provides to organisations. The innovation of transforming manufacturing-based businesses for the digital era. The granular, real-time insights, flexibility and automation achieved by IoT can empower the manufacturing industry in terms of operations and high profitability.

Solution Analysts is a renowned service provider of IoT in manufacturing industry. As a leading IoT application development company, we offer robust and secure solutions for the manufacturing domain with the goal to improve internal processes and generate high ROI.

sales@solutionanalysts.com

sales@solutionanalysts.com biz.solutionanalysts

biz.solutionanalysts